How Do Air Source Heat Pumps Work?

Air source heat pumps are a modern solution for heating your home and providing hot water. They harness the power of the outside air, even when temperatures drop significantly, to generate heat energy. This energy is then used to warm your radiators, underfloor heating system, or hot water tank. There are two main types of heat pumps used in homes: air-to-water and air-to-air heat pumps, with air-to-water being particularly suited to British homes built with a wet heating system, providing an efficient way to transfer heat through your home.

Air source heat pump systems are not only renewable but can also be cost-effective, saving you money in the long term through energy bill savings. They require less energy than traditional heating systems and are powered by electricity which is a greener option for reducing your carbon footprint, providing that your electricity is produced by renewable sources. Furthermore, certain government incentives such as the Boiler Upgrade Scheme can help with the initial costs, and help homeowners in England to make the shift.

Heat Pump Overview

Heat pumps are emerging as the number one choice for domestic heating for homes and buildings throughout the UK, the advances in technology and a deeper understanding of how to maximise the output of heat pumps mean that heat pumps are here to stay.

Gas Boiler Ban In 2025

The UK government has finally confirmed plans to ban gas and “hydrogen-ready” boilers in new homes built in England starting in April 2025. This decision comes after a long-awaited consultation on low-carbon building standards.

The proposals suggest that heat pumps will likely become the standard heating system for new homes. This aligns with the government’s goal of making all new houses “net zero ready” by 2025, meaning they’ll produce very low levels of carbon emissions.

The consultation process also ruled out alternative options like hybrid heat pumps and “hydrogen-ready” boilers for new builds. This decision was based on the conclusion that using any fossil fuel heating system, even those designed for future hydrogen use, wouldn’t achieve significant carbon reductions, hindering progress towards net zero.

Expenses of Heat Pump Installations

It is no secret that the cost of installing an air source heat pump is a significantly larger expense than a combi boiler. Yet, over a few years, the higher upfront cost gradually balances out due to the lower consumption of energy and in turn, reduced energy bills. To sweeten the deal, a £7,500 subsidy from the Boiler Upgrade Scheme brings the opportunity to install a heat pump to a much wider audience than before, by bringing costs in line, or sometimes to be even cheaper than the cost of traditional heating systems.

Types Of Heat Pumps

There are two types of heat pumps that make up over 99% of all heat pumps sold:

- Air-to-Air: Warms or cools your home by funnelling outdoor air through a duct system.

- Air-to-Water: Transfers heat into a water heating network for your radiators or underfloor system.

For the purpose of this guide, we will be mainly focusing on air-to-water heat pumps. In the UK most houses are built with a wet heating system which is connected to radiators or underfloor heating. Due to the UK being a colder country in general, wet systems are favoured to keep homes warm in the winter. Air-to-air systems require ventilation ducts to be installed in homes which isn’t a standard practice for our English homes, this is why air-to-air systems are more common in warmer countries that require cooling.

Will Heat Pump Prices Come Down?

While heat pump installation costs are based on factors like pump capacity and installation complexity, you can anticipate substantial savings on your annual heating expenses, sometimes saving up to two-thirds. The systems are impressively efficient, with operating efficiencies of over 400%, compared to traditional boilers at 90%.

If you are banking on costs reducing before you install a heat pump, then you are likely to be waiting forever. I have been working in the industry for over 10 years, and the costs have only gone in one direction, which isn’t likely to change any time soon.

There are a few reasons why costs are going up, by looking at the total cost of an installation, it is hard to see where the cost reductions are going to come from. The components of a heat pump are predominantly manufactured in Asia, which results in large shipping expenses to get the equipment around the world to us. Other essential materials required like copper piping, or water cylinders do have consistent pricing which has seen above inflation increases over the last 20 years. To install the system, plumbers and electricians will be required, with work spread over several days, there is already a shortage of tradesmen which is pushing labour prices to highs never seen before. There are also other essential charges for businesses, such as office staff and memberships to schemes such as the MCS, and HEIS.

There is the possibility for funding levels to change however, which could go up or down for the consumer. The British government have a track record of unpredictability, however in my opinion I think it is highly unlikely that further funding will be made available due to the current economic climate. The Boiler Upgrade Scheme is confirmed to run until at least March 2025, which means the government’s £7,500 voucher will significantly reduce the net cost of installing a heat pump until then.

One factor which can help you control costs the most is how well your home is insulated. A well-insulated home ensures minimal heat loss, enhancing the pump’s performance and leading to better savings, a well insulated home will also mean you require a smaller heat pump capacity, smaller radiators and this results in lower upfront installation costs.

Remember that energy efficiency not only reflects on your energy bills but also contributes to a more sustainable living environment. Hence, while the initial price might appear steep, the long-term benefits of a heat pump system are both financially and environmentally significant.

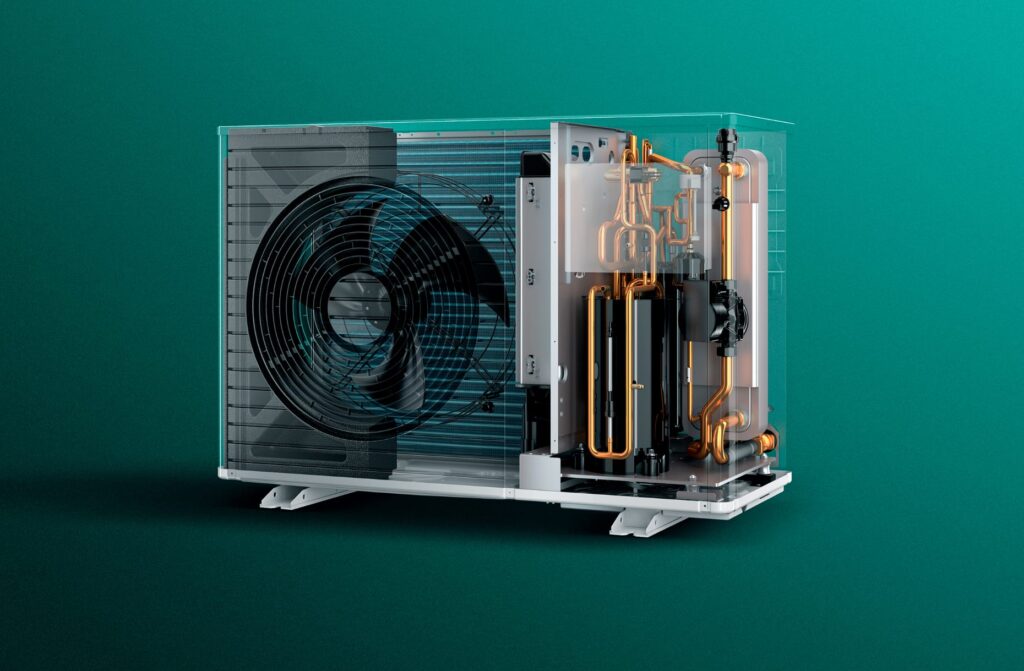

Heat Pump How It Works – Explained

A heat pump operates by moving heat from one location to another using a refrigerant. This system uses the thermal energy present in outdoor air or ground to heat your home. It’s a bit like your fridge, but instead of keeping things cool, it warms your living spaces.

Principles at Work:

- Thermal Transfer: Heat naturally travels from warmer to cooler areas. Heat pumps exploit this by collecting heat from the environment and transferring it indoors.

- Cycles of Operation: Inside the pump, a refrigerant captures external heat as it evaporates into a gas, then a compressor raises the temperature of this gas.

- Efficiency: Despite requiring electricity to operate, heat pumps are energy efficient. They do not burn fossil fuels, making them a cleaner choice for heating.

Due to their design, they have the ability to function in a spectrum of temperatures, you can rely on heat pumps to provide warmth even in the depths of a cold British winter! Some models will still work well at temperatures as low as -25°C, which is far below the lowest temperatures that are seen in the UK.

Types of Air to Water Heat Pumps:

- Air Source: These extract heat from the air. An external unit with coils and a fan draws in outdoor air, heats the refrigerant, then sends it indoors into a wet heating system.

- Ground/Water Source: These gather heat from the ground or water. They work similarly but start with warmth from underground or water sources to provide heating.

When you have a heat pump installed, a loop system consisting of an evaporator coil, compressor, and condenser coil works continuously. This means the process of absorbing and releasing heat is sustained, ensuring your home stays warm consistently.

Understanding the Mechanics:

The external part of an air-source heat pump features coils filled with refrigerant. The outside air is pulled over these coils by a fan, heating the refrigerant, which evaporates and is compressed to further increase the temperature. The refrigerant then travels indoors to release the captured heat before cycling back outside to restart the process.

Adopting heat pump technology has become increasingly popular for their efficiency and sustainability, making them a favoured choice in future proof home designs.

Fundamental Operations of a Heat Pump

Heat naturally moves from an area of higher temperature to one of lower temperature, but the reverse requires additional energy to be expended. Deploying a heat pump allows this process to occur, transferring warmth in a manner opposed to its natural flow.

Basic Concept

The heat pump operates by consuming less energy (work) to move a given quantity of heat, hence its advantage over other heating methods like electric resistance heating, which typically requires substantially more energy.

Energy Transfer Ratio

To shift heat Q from a cooler exterior to a warmer interior, the amount of energy W needed can be expressed as:

- Work Done (W): Represents the energy employed by the heat pump’s compressor.

- Heat Moved (Q): The heat shifted from the colder zone to the warmer zone.

- Coefficient of Performance (COP): A measure of the heat pump’s efficiency at the prevailing temperatures of the two regions involved.

The equation is given by:

W = Q / COP

The efficiency of a heat pump is significantly influenced by its COP, which is typically greater than one (can be 1:4), meaning that it needs less work to transfer heat compared to the amount of heat it moves. However, it’s important to note that the COP decreases as the higher-temperature environment’s temperature climbs, or the external temperature decreases, requiring more energy per unit of heat transferred.

Calculating Efficiency

Envision a heat pump working along the confines of the idealised reverse Carnot cycle:

- Low-temperature reservoir: Situated at 270 K (-3°C)

- High-temperature reservoir: The interior of a building at 297 K (24°C)

The kelvin (abbreviated to K), less commonly called the degree Kelvin (o K), is the Standard International ( SI ) unit of thermodynamic temperature.

Consider an air source heat pump scenario where the outside temperature is -3 degrees Celsius, equivalent to 270 Kelvin, and the inside temperature of a building is maintained at 25 degrees Celsius, equivalent to 298 Kelvin. The coefficient of performance (COP) of the heat pump is 4, meaning for every unit of energy input, the heat pump can transfer 4 units of heat energy.

Given this, we can understand how the heat pump operates. At -3 degrees Celsius (270 K), the heat pump extracts heat from the outdoor air and transfers it into the building. Since the COP is 4, for every unit of energy (e.g., electricity) the heat pump consumes, it can move 4 units of heat from the outdoor environment to the indoor space.

So, to raise the indoor temperature from 270 K to 298 K (25 degrees Celsius), the heat pump needs to transfer a certain amount of heat energy. With a COP of 4, it requires only 25% of the energy input compared to the amount of heat energy it transfers. In this case, the heat pump would effectively add heat to the indoor space, ensuring it reaches and maintains the desired temperature of 298 K (25 degrees Celsius).

Practical Considerations

It’s vital to be aware that the theoretical heat output may not always be achievable in practice. External factors, such as suboptimal placement of the unit where airflow is restricted, could deter performance. This is also an area where the different brands of heat pump will give a different performance output, so be sure to choose a brand with a good reputation and high performance figures.

Installation Stages of Air Source Heat Pumps

Air source heat pump installation is a structured process requiring a MCS qualified installer to evaluate, plan, and execute the setup. Below is an overview of what to expect during the installation stages.

Step 1: Evaluating Your Premises

The process kicks off with a professional assessment of your property to determine the heat pump’s optimal placement, considering factors like insulation levels, heat requirements, and radiator upgrades. A survey is sometimes done by a third party company for a fee, by outsourcing the survey, you can feel confident that you will get an impartial assessment of your home and heating requirements. Once your assessment is completed, the outcome of the survey will allow you to make an informed choice on the heat pump size, brand and radiator upgrade requirements, without the influence of a company that may not have your interests as their main priority.

Step 2: System Design and Quotation

Once your assessment is completed, the outcome of the survey will allow you to make an informed choice on the heat pump size, brand and radiator upgrade requirement.

The system design will include an estimation of the total cost, influenced by the size of the heat pump and the complexity of the installation.

Step 3: Implementing the Installation

With the design agreed upon, the actual installation can begin. The first step will be the draining down and removal of the existing system, usually existing pipework is kept in place if it is in good condition. The new heat pump, hot water cylinder and radiators are then installed with new wiring, the system is then filled up with water and ready to turn on.

Step 4: Certification and Functional Testing

On completion, pressure tests are conducted and a start up cycle to verify the heat pump system‘s operational functionality. Safe operation and electrical sign off have to be done before it’s fully handed over for your usage. You’ll receive key MCS certification and user guide documents with warranty information.

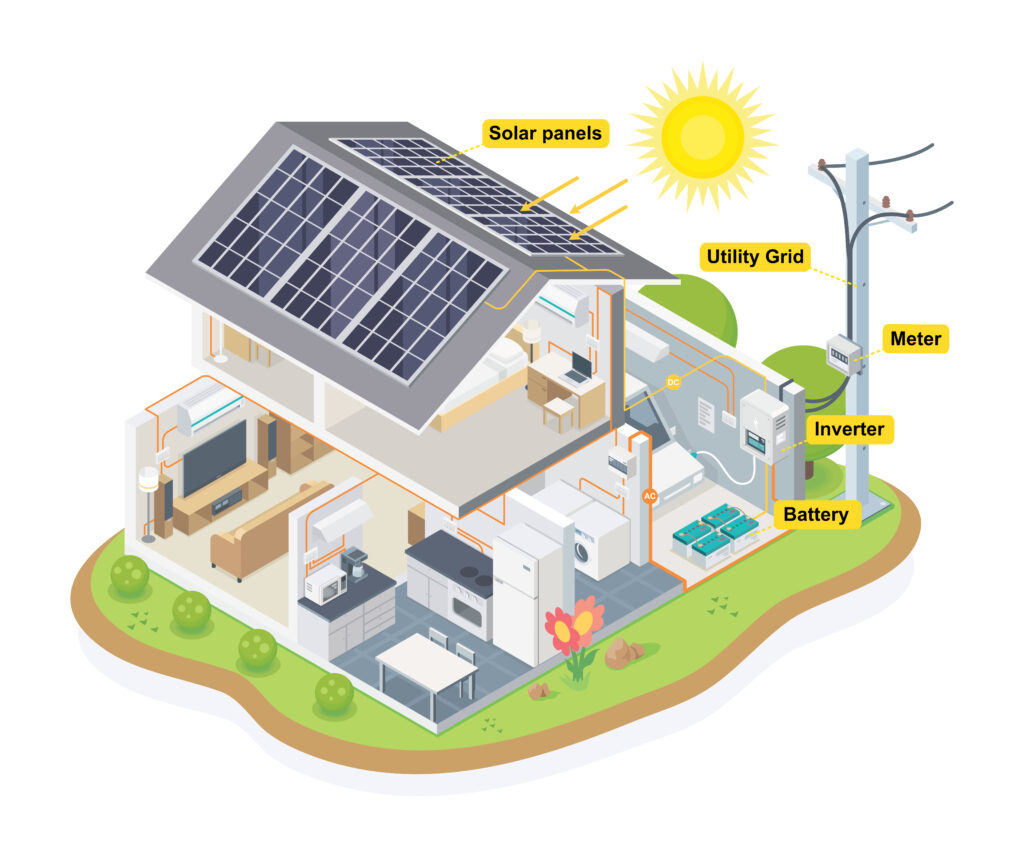

Cost-wise, an air source heat pump might entail an expenditure between £12,000 and £18,000, though this varies with several factors. However, by calculating savings over time, through reduced energy costs and financial incentives, such as the Boiler Upgrade Scheme, the initial investment can be efficiently recovered, and savings turbo charged if you combine with solar panels and smart energy tariffs!

Government Grants for Heat Pumps

Boiler Upgrade Scheme

As part of the transition to greener energy, the UK government’s Boiler Upgrade Scheme means you could claim £7500 when you switch to a more efficient air source heat pump. You must own your property and having an older non-renewable heating system, this includes all fossil fuel systems, as well as electric boilers and storage heaters. To get access to the grant, you must be working with an MCS accredited installer and choose an approved heat pump model.

You can find a local heat pump installer by filling in your details with Compare Renewables.

Potential Reductions in Heating Expenditures

Upgrading to an air source heat pump can be cost-effective over time. These systems are known for their exceptional efficiency, boasting a coefficient of performance (COP) that can reach over 400% in efficiency. In simpler terms, an air source heat pump can provide up to four times the heat energy per unit of electricity it consumes, offering marked savings on your energy bills. This efficiency measure starkly contrasts with fossil fuel-based heating systems, such as boilers with efficiencies between 70% to 95%, equating to 0.7 to 0.95 in COP.

Considering factors like your current heating setup, property size, and the heat pump’s efficiency, the potential savings available for grabs could swiftly counterbalance the initial installation costs. With heating demands ever-increasing, air source heat pumps are setting the standard for the new super efficient, environmentally friendly and normal way to heat your home, which is a winning formula accross the board in our eyes.

Heat Pump Costs

Influencing Factors on Heat Pump Expenses

Acquiring a heat pump involves contemplating several key aspects that will affect the financial investment:

- Home Dimensions: The larger your residence, the larger the heat pump will need to be, which does have a cost increase incrementally. Yet, selecting the right size heat pump is important, it needs to be large enough for your needs, but not vastly oversized. A heat pump should be oversized by around 10% to 30%, as this will allow for changes in the home over time, but ensure the pump is not too big, which would incur unnecessary higher running costs.

- Heating Demands: Your household heating demands as also as important as the size, these are shaped by the insulation levels of the walls, roof, floor and windows. The greater the insulation levels will mean a smaller system is required, which will save on upfront installation costs and also long term running costs.

- Pump’s Brand: Top tier brands may command a premium price; however, they can offer superior quality and efficiency and although there could be a higher initial price, the return on investment will pay for itself through your reduced heating bills. Brands like Mitsubishi, Vaillant & Samsung offer good quality heat pumps and are known for their reliability.

- Efficiency Rating (CoP): Pumps with a higher Coefficient of Performance (CoP) deliver better efficiency, but also note that the COP will vary depending on the flow temperature of the water in the system, if you are comparing systems, ensure you compare the COP at 50 degrees.

- Renovation Expenditures: Should insulation be needed to keep your house warm these should be added to the total cost, there may also be some new radiators required when upgrading to a heat pump. New radiators are needed to make sure the rooms heat up as fast as possible which will reduce running costs.

Estimated Costs for Air Source Heat Pump Installation

When adding up the costs of an air source heat pump, the upfront costs are softened because you should qualify for the Boiler Upgrade Scheme voucher, which is a sizable contribution of £7,500.

Air Source Heat Pump Cost

Single Air-to-water heat pump setups come in around 4 or 5 different sizes per brand, from 5kw up to 17kw. The smaller and thermally sound houses need a smaller heat source pump, the bigger and older houses usually need a large heat pump to keep their home warm, which usually incurs a bigger price tag. The heat pump prices below are before the £7500 voucher has been taken off, and include some radiator upgrades.

- A Smaller House / Good insulation: Expect heat pump installation costs between £12,000 and £15,000. (£4500 to £7500 to pay when using the grant)

- A Large House: Heat pump costs can be between £13,500 and £18,000. (£6000 to £10,500 to pay when using the grant)

- Annual Upkeep: On average £150 – £250 for annual servicing, this is required to keep warranties valid.

Upkeep and Handling of Air Source Heat Pumps

To guarantee optimal performance and extend the lifespan of your air source heat pump, appropriate upkeep is vital. Here are streamlined strategies to maintain your system effectively:

- Routinely Check the exterior unit and remove any debris that could impair the fan blades.

- During winter, prevent snow and ice from amassing on the unit to avoid damage, a little bit would be fine, but if there was heavy snowfall you would need to create space for airflow 1m around it.

- Check the refrigerant and anti-freeze levels – this is to be done on the annual service, but the refrigerant levels shouldn’t change in most systems, the anti-freeze may need topping up.

- Schedule a yearly service to verify all components, including the compressor and heat exchanger, are in good condition with no leaks or faults. Your installer might offer a service plan when you purchase the system.

Just using a little bit of common sense and caring for your air source heat pump system like you would with outher parts of your home reduces the need for repairs and assures the system is operating efficiently. A heat pump by design needs less maintenance than almost all other types of heating system, but with little extra effort, they are also extremely reliable.

Comparing Air Source Heat Pumps with Conventional Heating Methods

Air Source Heat Pumps vs Gas Boilers

Gas boilers, traditionally common in british homes, utilise natural gas to create heat. In comparison, air source heat pumps are a more efficient alternative by extracting warmth from the outside air.

Both offer their own set of benefits and considerations. This is the first of 3 system comparisons, so let’s compare these heat pumps vs gas boilers to help you make an informed decision for your home.

Installation Costs:

Air source heat pumps typically involve higher upfront costs compared to gas boilers. Although the installation costs are high, the Boiler Upgrade Scheme can help offset these costs, making air source heat pumps a more financially viable option and bringing them to a level where they are an attractive option against a gas boiler.

Gas boilers, on the other hand, generally come with lower installation costs. The equipment is often more affordable, and installation is relatively straightforward for homes already connected to mains gas. However, it’s important to consider potential future regulations, such as the upcoming ban on gas boilers in new homes from 2025 and the phasing out of gas boilers over the proceeding 10 years.

Running Costs:

Despite the higher upfront costs, air source heat pumps offer significant savings in running costs over time. They are highly energy efficient, meaning they can provide 4 to 5x more heat energy per unit of electricity consumed compared to gas boilers. This results in lower energy bills and long-term cost savings for homeowners.

Gas boilers have historically been favored for their relatively low running costs, especially in areas where natural gas is readily available. Gas boilers are the cheapest of all the fossil fuel systems that could heat your home. However, fluctuations in gas prices over time can impact their affordability over the longer term.

Carbon Footprint:

After manufactuing an installation, air source heat pumps can have no carbon footprint compared to gas boilers. This is because they rely on electricity rather than burning fossil fuels for operation. As the UK continues to transition towards renewable energy sources, the environmental benefits of air source heat pumps are expected to increase further.

Gas boilers are a major source of carbon emissions in residential heating systems, according to GOV.UK, over 38% of the UK’s gas usage is for heating homes. Burning natural gas releases carbon dioxide and other pollutants into the atmosphere, contributing to air quality issues and environmental concerns. With the UK government’s commitment to achieving net-zero emissions, air source heat pumps are their chosen heating system to help achieve their net-zero goals.

In conclusion, while both air source heat pumps and gas boilers offer heating solutions for homes, air source heat pumps are the stand out winner for their energy efficiency and lower carbon footprint.

See our extended review of Air Source Heat Pumps vs Gas Boilers.

Air Source Heat Pumps Vs Oil Boilers

Our second heat pump comparison is with oil boilers. Oil boilers operate similarly to gas boilers but use oil as a fuel, making them less favourable where a gas supply is unavailable.

Installation Costs:

We already know air source heat pumps typically involve higher upfront costs compared to oil boilers. However with the Boiler Upgrade Scheme offsetting the costs, there will be between £4500 to £10,500 to pay.

Comparing this to oil boilers on the other hand, generally come with supply and installation costs that range from £4000 to £12,000. The equipment is often in the same price range, but with fossil fuels being phased out, oil systems are set to become rarer with installations and parts becoming more expensive.

There is also a need for an oil tank which can cost £1500 to £5000 if you dont already have one installed. Just like with mains gas, there is the potential of environmental regulations regarding oil heating having a negative effect too.

Running Costs:

Heat pumps offer significant savings in running costs over time, especially if you can compine them with cheap or free electrcity from solar panels. The efficiency of oil boilers is comparable to that of gas boilers, but they suffer from a greater price volatility in the oil market oil and a more significant environmental impact.

Oil boilers have historically been favored by residents who are off the mains gas network, this is due to oil being the fuel that provides the lowest running costs available to them, which is the best of bad bunch situation. However, oil prices over time are significantly higher than mains gas and even more higher than a heat pumps electricity requirement, which makes oil on par with bottled gas, as the worst choice of fuel based on the ongoing running costs.

Carbon Footprint:

As covered already, air source heat pumps have no carbon footprint, when compared to oil boilers there is only one winner. Oil boilers are a significant source of carbon emissions, burning oil releases carbon dioxide and other pollutants into the atmosphere, contributing to air quality issues and environmental concerns. It is likely that oil boilers will be outlawed in the not too distant future.

In conclusion, while both air source heat pumps and oil boilers offer heating solutions for homes, air source heat pumps are the clear winner across the board, the installation costs are comparable and from a running cost and environmental point of view, an air source heat pump is the winner by a mile.

Air Source Heat Pumps vs Electric Storage Heaters

Our third and final comparison is heat pumps vs storage heaters. Electric storage heaters are seen in properties without access to gas and use off-peak electricity to store heat for release during the day.

Installation Costs:

Air source heat pumps typically involve higher upfront costs compared to electric storage heaters. There is no need for a wet system and expensive copper piping, plus lower labour costs, although they are still not the cheapest system to install.

The cost of a system will range from an average of £250 to £800 per radiator, which means a system with 10 radiators could cost £2500 to £8000. In comparison a heat pump is in the range of £4500 to £10500, which means there will be some situations when a heat pump could be cheaper, but most houses a heat pump is likely to be the higher cost. A good measure would be if there is 15 radiators in a house, a heat pump is likely to be cheaper, however for a smaller house, the initial cost of storage heaters will be less.

Both systems are powered by electricity so there is no supply issues or variances in cost for this aspect of the installation.

Running Costs:

Despite the higher upfront costs, air source heat pumps offer significant savings in running costs over time. Giving at least 4x efficiency over storage heaters and with both systems are running on eletricity, that means a heat pump will be 4x times cheaper to run than storage heaters.

There could be a slight variance in those figures depending on what your day and night time electricity tariffs are, plus if your home has solar panels installed, which would favour air source heat pumps. This is because the solar panels will provide free electricity in the day time, which in turn will give you free heat.

Electric storage heaters typically have inefficiencies in heat retention. They often require charging during off-peak hours when electricity tariffs are lower, but may struggle to retain heat effectively throughout the day, resulting in unnecessary higher energy consumption and associated costs with day time electricity.

Carbon Footprint:

Air source heat pumps have a lower or equal carbon footprint in comparison with electric storage heaters. This is because both systems rely on electricity rather than burning fossil fuels for operation.

As both systems use electricty, they could be carbon neutral, providing the electrcity is generated from a renewable source. However a heat pump uses 4x less electricty, as the UK still has fossil fuel power stations for electricty generation, it does position storage heaters behind air source heat pumps from an environmental point of view.

In conclusion, while both air source heat pumps and electric storage heaters offer electric heating solutions, air source heat pumps stand out for their energy efficiency and carbon footprint, they are also simliar on installation costs, which means overall heat pumps are the better choice for as the best heating system.

Heat Pumps vs Boilers vs Storage Heaters

This master table provides a side by side comprehensive overview of the key differences between air source heat pumps, gas boilers, oil boilers, and electric storage heaters.

| Aspect | Air Source Heat Pumps | Gas Boilers | Oil Boilers | Electric Storage Heaters |

|---|---|---|---|---|

| Installation Costs | Higher upfront costs, but with government incentives to offset expenses. | Lower upfront costs, particularly if your home is already connected to mains gas. | Average upfront costs, with extra to pay if your home doesn’t have an oil tank already. | Average upfront costs, but no wet system in place if you switch to another type. |

| Running Costs | Best energy efficiency, long-term savings on energy bills, can combine with solar panels. | Lowest of the fossil fuel running costs, no way to combine with solar panels | Historically unstable running costs due to fluctuations in oil prices. | Highest running costs due to being very inefficienct. |

| Carbon Footprint | Lower carbon emissions due to reliance on electricity rather than burning fossil fuels. | Higher carbon emissions from burning gas. | Higher carbon emissions from burning oil, plus inefficient delivery by road | Lower carbon emissions, depending on the source of electricity generation. |

The outcome is that overall, air source heat pumps represent a significant step forward in heating, from an financial and environmental point of view, the heating landscape is changing to a renewable one, although the costs are higher initially, the long term view shows that air source heat pumps are the clear winner. If you are struggling to pay for the heat pump up front, a lot of installers offer finance plans, which although paying interest doesn’t sound appealing, your savings over time should outweigh the interest payments and long term savings in comparison to other heat sources.

Air Source Heat Pumps For The Environmental

Annual Carbon Emissions

It is known that traditional heating systems have a considerably high carbon footprint. To offer contrast, let’s look at a comparative analysis:

Based on average household consumption a study has shown how many kilograms are emitted per heating system:

Gas Boilers – 2720kg

Oil Boilers – 5240kg

Air Source Heat Pumps – 780kg (if the electrcity is generated from fossil fuels) or 0kg (if electricity is sourced from renewables)

Just to put this into perspective, the 5240kg of Co2 emissions is enough power to charge a smartphone 620,0oo times, or 2600 litres of diesel consumed by a car.

If the nation could switch over to an air source heat pump (ASHP) on each property, the UK would see a drastic decrease in carbon emissions, especially if the electricity powering it comes from renewable sources like solar PV & wind farms, effectively cutting emissions to zero. Besides being a huge part of moving towards a net-zero country, renewable technologies also give bill payers economic benefits over the long term.

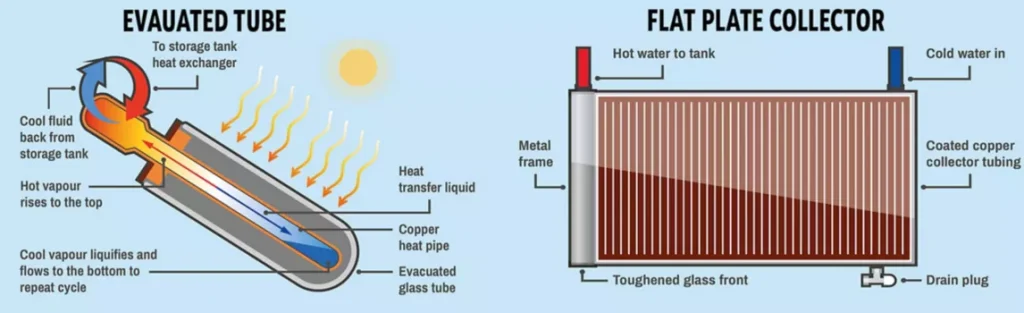

Innovative Refrigerants and Their Significance

Recent advancements, such as the introduction of R32 and R290 refrigerants in heat pumps, hold high hopes for even better environmental outcomes. R32, having a lower global warming potential (GWP) than its predecessors, presents a stride towards more ecological heating systems. R290, or propane, is notable for its negligible GWP, enhancing the eco-friendly credentials of ASHPs.

The R32 refrigerant has a GWP of 675, and the R290 heat pumps have a GWP of 657, which is important, by 2025 all refrigerants with a GWP of over 750 are being phased out of use. These refrigerants used in todays heat pumps are essential for longevity in new green heating solutions.

Frequently Asked Questions

How Do Air Source Heat Pumps Get Warmth

Air source heat pumps absorb heat from the atmosphere and intensify it to warm your residence and water supply. The operation is analogous to a refrigerator but in reverse, drawing in air, even at temperatures as low as -25°C, to maintain a comfortable indoor climate throughout the year.

What Are The Benefits Of Getting An Air Source Heat Pump?

Opting for an air source heat pump can bestow multiple benefits:

- Exceptional energy efficiency, potentially reducing heating expenditure

- Provision of both heating and hot water

- A pathway to a carbon-neutral operation given the use of electricity over fossil fuels

- Eligibility for financial incentives like the Boiler Upgrade Scheme

What is the Cost To Install An Air Source Heat Pump?

Investing in an air source heat pump entails costs affected by your home’s scale, installation intricacy, and the chosen model. While prices typically span from £12,000 to £18,000, government contributions of up to £7500 can significantly mitigate the expense.

What Is The Difference Between Air-to-Water and Air-to-Air Systems?

Differentiate between two air source heat pump models:

Air-to-water systems: Integrate with water-based heaters like underfloor setups or radiators, providing central heating and hot water.

Air-to-air systems: Directly warm your home’s air, suitable if you have an existing network of fans or ducts but ineligible for the Boiler Upgrade Scheme.

Is a Mitsubishi Ecodan Heat Pump Good?

The Mitsubishi Ecodan is a great heat pump, it excels in reliability and efficiency, it comes with the melcloud control app and a 1:4 heating efficiency ratio at 50°C output temperature. It is once of the best heat pumps you can buy and is available for a range of property sizes.

Should I Get An Air Source Heat Pump or Conventional Heating System?

Air source heat pumps surpass traditional heaters in energy efficiency and environmental friendliness, providing heat transfer from ambient air, thus trimming your bills and carbon footprint. They future-proof your home, ready for upcoming regulations disallowing fossil-fuel-derived heat in new homes post-April 2025.

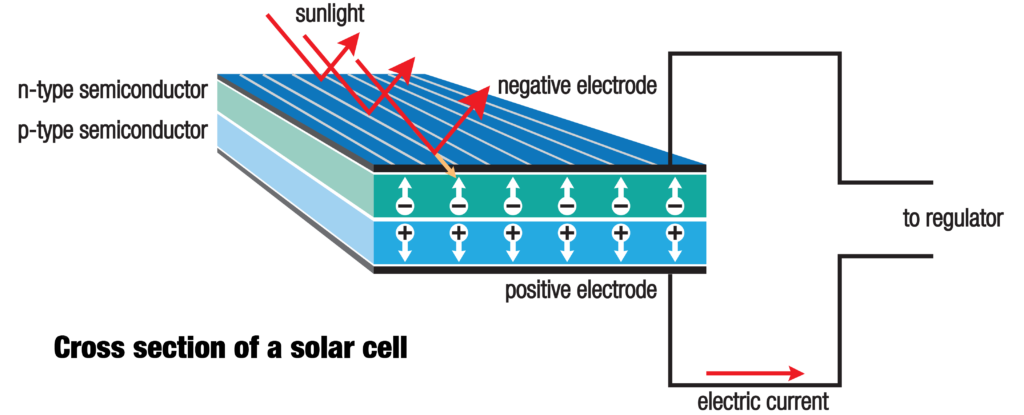

Does Solar Panels Work With Air Source Heat Pumps?

Adopting an air source heat pump is a stride towards sustainability, particularly when allied with solar photovoltaic (PV) panels and battery storage, cementing an eco-friendly, self-sufficient home energy system.

Take a look at our ‘complete guide to solar panels‘ for a full breakdown of solar panels and battery storage in your home, plus we also have a guide called ‘how many solar panels do I need‘, which will explain what you should be looking for once you have decided to get a solar system installed

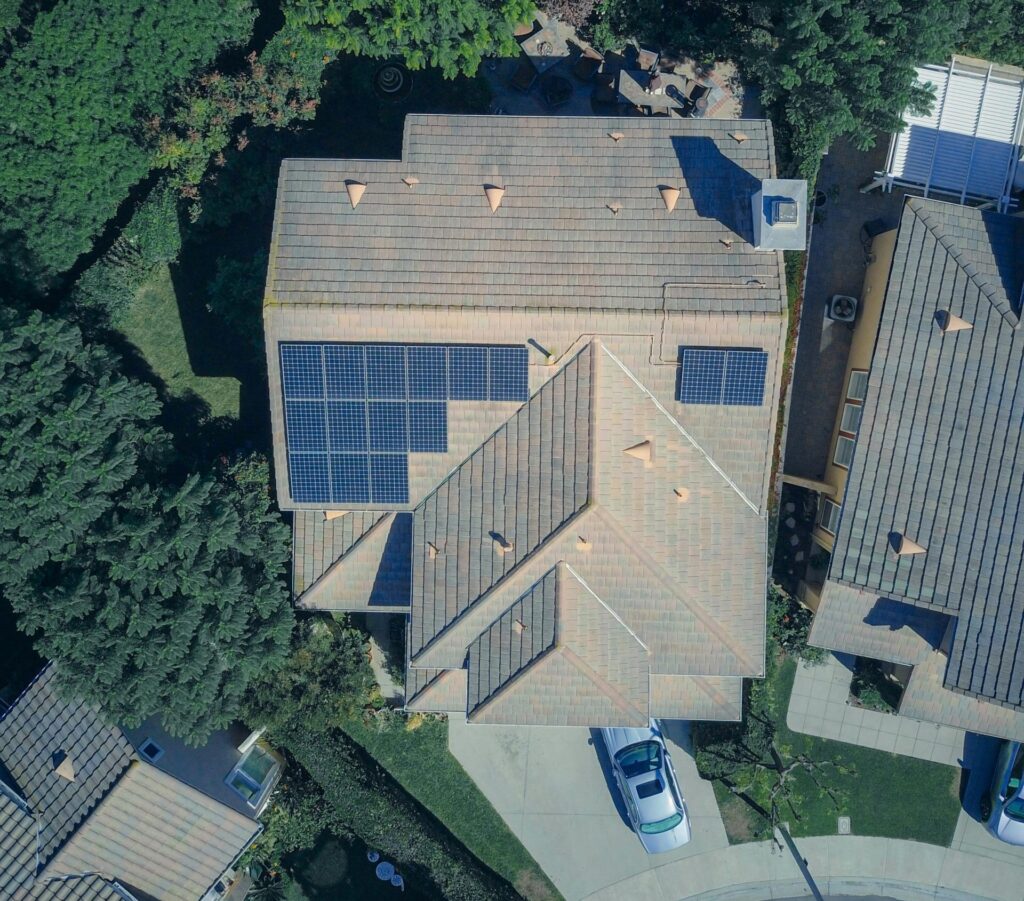

Links

The surroundings of the solar system are also a key factor. When designing your solar array layout, seek to maximise the efficiency of each panel by avoiding shade from chimneys, vents, trees, or neighbouring structures.

The surroundings of the solar system are also a key factor. When designing your solar array layout, seek to maximise the efficiency of each panel by avoiding shade from chimneys, vents, trees, or neighbouring structures.